800.376.7867

Machine Shop

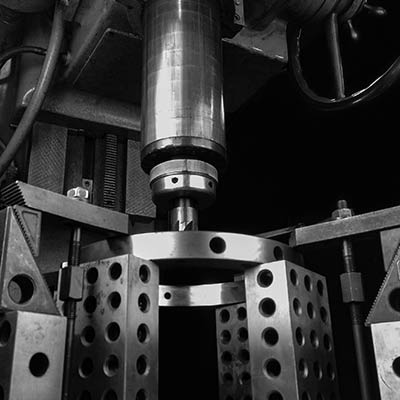

For over 25 years, AVI's machine shop has served a multitude of industries... Our clients utilize a myriad of our precision manufacturing and engineering services. AVI has a reputation of building high quality parts with outstanding accuracy, quality and finish while developing and maintaining long lasting relationships with our clients. Our machine shop is large enough to meet most of our customers needs while providing focused project and personal attention.

Our clients utilize a myriad of our precision manufacturing and engineering services. AVI has a reputation of building high quality parts with outstanding accuracy, quality and finish while developing and maintaining long lasting relationships with our clients. Our machine shop is large enough to meet most of our customers needs while providing focused project and personal attention.

In most instances, our entire process is done in one location which increases efficiency, improves quality control, and controls production costs for our clients as well as increasing communications between our employees and customers

We can provide simple and complex machining in a wide variety of simple and complex materials. AVI will do one off custom jobs to large-scale productions. AVI has been able to create custom parts where other companies have not succeeded or lacked the capabilities. Our clients choose AVI because we have the ability to reverse engineer a product and create “One of a kind” parts. Our machine shop foreman is a tool and die maker with over 33 years of experience.

We are conveniently off of exit 46 on Route 8 in Torrington.

Services Include...

- Heat Treating

- Cladding

- Tig and Mig and Stick Welding

- Metallurgical and Mechanical Testing

- NDT (Non-Destructive Testing)

- Premium Threading

- Coatings

- Press Rebuilds: Slab Side, Post, and Transfer

- Hardness Testing (HBW, HRC, and HRB)

- Non-Destructive Thickness Measurements

- Drilling & Tapping

- Sawing

Some of the industries we service include...

- Power Generation

- Transportation

- Marine

- Heavy Machinery

- Waste Water Treatment

- Manufacturing

- Construction

- Chemical and Petrochemical

- Paper Plants

- Medical

- Mining

Our Machine Shop includes the following equipment and capabilities...

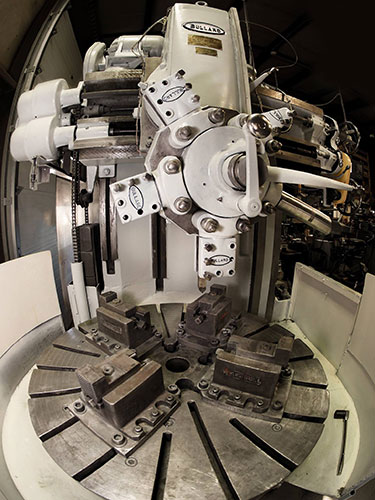

- Lathes for turning, which range in size from an 8” swing with 24” between centers, all the way up to a 51” swing with 16’ between centers. We also have two vertical turret lathes with a 36” and a 54” table.

- A large Lucas Horizontal Boring Mill with 86” X 96” X 72” of travel, as well as a few Bridgeport milling machines with 12” X 22” of travel.

- A precision Norton Cylindrical O.D. grinder with a 30” X 3” wheel, with a 40” swing and a 12’ table. This machine is capable of grinding diameters to within (+ or -) .0001”. It can also hold that diameter (within .0005”) upwards of 11’ long between centers.

- A precision Atlantic 7000 Jig Borer, with a 28” built in Optical Rotary Table, capable of 24” X 50” of travel.

- Surface grinding capabilities ranging from 8” to 35” of travel.

- A state-of-the-art Schenck HM4B Analysis, Hard Bearing balance machine that can handle up to 7,000lbs. As well as, a Dyna Balance Machine that can hold up to 20,000 lbs with clearance to spin an 8’ diameter.

- We are also capable of electrical testing windings with a Digital Baker (Model D15R/D65R). It has surge test capabilities with output voltage up to 15kv and an 800 amp peak current, and is capable of a DC High potential test.

- 50,000lb P&H Overhead crane, six forklifts (ranging in lift capacity from 2-30,000lbs.)